. 26/09/2024 11:19 AM

A Step Towards Sustainable Carbon Management

India has embarked on an ambitious project to construct its first CO2-to-methanol pilot plant in Pune, Maharashtra. With a production capacity of 1.4 tons per day, this facility is a collaborative initiative under a Public-Private Partnership (PPP) between the Indian Institute of Technology (IIT) Delhi and Thermax Limited. Supported by the Department of Science and Technology (DST) with a budget of ₹31 crore ($3.7 million), the pilot plant aims to advance carbon capture and utilization (CCU) technologies while aligning with India's commitments to sustainable development and emissions reduction.

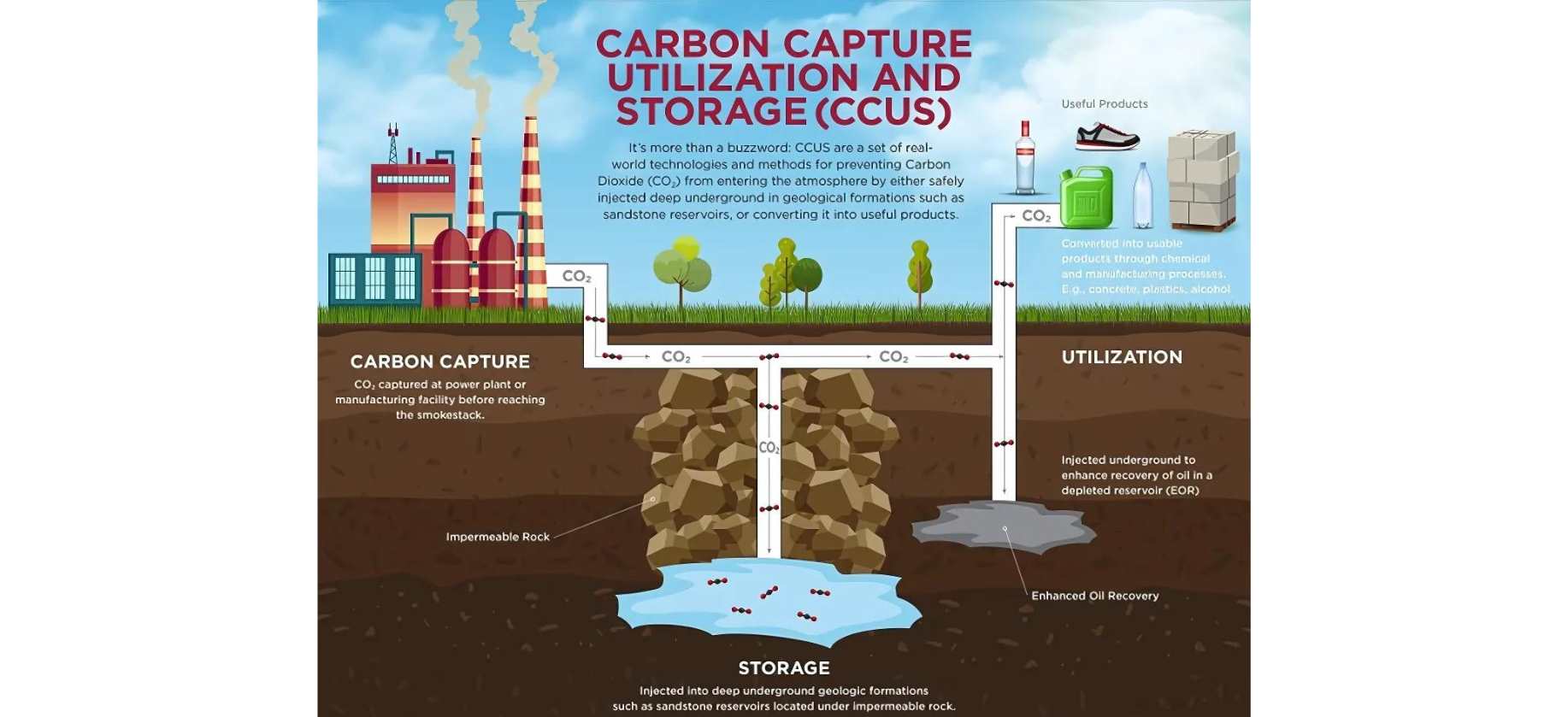

CO2-to-methanol conversion is an innovative approach to addressing climate change by capturing carbon emissions before they are released into the atmosphere. This process primarily targets emissions from industrial sources, such as fossil fuel-based power plants, as well as utilizing direct air capture technologies.

The conversion process involves several key steps:

Capture: Carbon dioxide is captured from large, stationary emitting sources. This includes technologies designed for both pre-combustion and post-combustion capture.

Transport: The captured CO2 is transported to utilization sites using pipelines or via shipping, rail, or trucks.

Utilization: At the destination, the CO2 can be used in various applications, such as methanol production, or injected into geological formations or depleted oil and gas fields for permanent storage.

Captured CO2 is then hydrogenated, reacting with hydrogen to produce methanol, a versatile fuel and chemical feedstock. This process not only helps in reducing greenhouse gas emissions but also provides a sustainable source of fuel.

The establishment of the CO2-to-methanol plant is significant for several reasons:

Decarbonization of Hard-to-Abate Sectors: Industries such as cement and steel, which are heavily reliant on fossil fuels, are among the most challenging to decarbonize. The plant could serve as a model for reducing emissions in these sectors.

Low-Carbon Hydrogen Production: Integrating coal gasification with CCUS technologies can facilitate the production of low-carbon hydrogen, further supporting energy transition efforts.

Achievement of Net Zero Targets: The advancement of direct air capture technology, combined with initiatives like the Pune plant, can significantly contribute to achieving net-zero emission goals.

While the potential benefits of CCUS are considerable, several challenges exist in the Indian context:

Cost Variation: The costs associated with carbon capture vary widely across different sectors, influenced by factors such as the source and concentration of CO2.

Limited CO2 Storage Capacity: There is a lack of comprehensive geological data on pore space availability, particularly concerning saline aquifers and basaltic storage.

Infrastructure Deficiencies: The absence of adequate infrastructure for the transportation and storage of captured CO2 poses a significant hurdle to scaling up CCUS technologies.

At the groundbreaking ceremony, Dr. Abhay Karandikar, Secretary of DST, emphasized the pilot plant's importance as a groundbreaking platform for showcasing and advancing indigenous CCU technologies. He noted that this initiative aligns with India’s Panchamrit targets, articulated by Prime Minister Narendra Modi during COP 26, which focus on reducing carbon emissions and promoting sustainable development.

Dr. Anita Gupta, Adviser at the DST, described the collaboration between IIT Delhi and Thermax as a “living lab” for CCU research. This facility will focus on developing new catalysts and processes for converting captured CO2 into chemicals, ultimately assessing the feasibility and commercial viability of such technologies.

Additionally, NITI Aayog, in conjunction with the Ministry of Petroleum, is developing policies to facilitate the introduction of 15% methanol-blended diesel, aimed at reducing India’s reliance on crude oil imports.

The CO2-to-methanol pilot plant in Pune represents a pivotal step towards enhancing India’s capabilities in carbon capture and utilization. By advancing indigenous technologies and addressing the challenges associated with CCUS, this initiative could significantly contribute to India's environmental goals and its commitment to sustainable energy solutions. As the nation continues to explore innovative strategies for carbon management, the insights gained from this pilot plant will be crucial for scaling up CO2-to-methanol conversion technologies and fostering a low-carbon future.